- Home

- >

- Denim & Belts

- >

- Washed Denim Jeans - Tapered Slim fit LLJ004

Washed Denim Jeans - Tapered Slim fit LLJ004

|

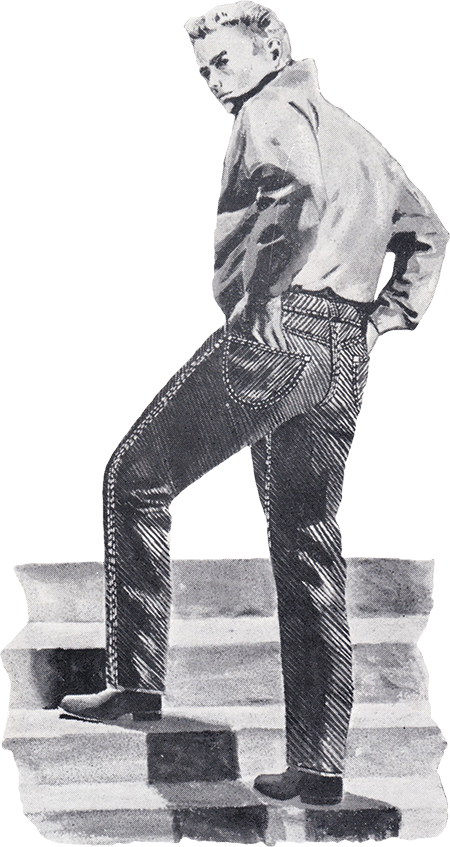

These denim jeans are made to our own specifications, each pair are entirely sewn by one pair of hands. The fabric we have chosen is very special, the finest 15oz, right hand twill, rope weave indigo denim, produced on 70-year-old machines in Okayama, Japan. The 15oz denim fabric is heavier than most jeans you will find and only 50 metres a day can be made. The 15oz denim fabric is crafted in Okayama using indigo rope-dyed yarn which is then woven on 70-year-old machines with a daily maximum capacity of only 50 metres. The fabric is then cut to our patterns and sent to Mr Kuniyoshi for assembling at his workshop where he sews each pair himself, just as each of our leather jackets is made by a single machinist. |

|

The logo's are applied at a small Okinawa embroidery shop which began decorating souvenir jackets for servicemen at the nearby US base during the Vietnam war. It was here, in 2013, that LL's Derek met Mr Kuniyoshi, the Jeans maker by chance. Mr Kuniyoshi recognised the jeans Derek was wearing and they got chatting, after, they visited Mr Kuniyoshi's nearby workshop where Derek was so impressed by the quality of his sewing and quality that we asked decided to make jeans together.

- Washing: These jeans have been washed, so are ready to wear. - Subsequent washing: Fans of this rope-weave style of denim will know that wearing it for three to six months before the first wash will encourage unique and desirable fade characteristics. The dark indigo denim will then develop distinctive subtle shades of blue at points of stress and wear -a snapshot of the way you live your life, however, they can, of course, be washed before that. - Prior to washing: we recommend closing the fly buttons and turning the jeans inside out and washing at a low temperature, never over 20C. This will help the fabric retain the dye for the longest period and produce the ultimate natural fade as your jeans age. Not only will they wear for a long time but they will look amazing too. |

|

|

|

Washed Denim Jeans - Tapered Slim fit LLJ004

ジャケットと同様に、私たちは少し特別なことをしたいと考え、最近ではジーンズも國吉氏によって日本で作られています。

國吉氏は本土のKAPITALで10年間ジーンズを作り、11年前に故郷の沖縄に戻り、Double Volanteを設立しました。

このデニムジーンズは、私たちの独自の仕様で作られています。

選んだ生地はとても特別で、岡山の70年前の機械で生産された最高級の15オンス、右綾、ロープ織りのインディゴデニムを使用しています。

15オンスのデニム生地は、一般的なジーンズよりも重く、1日に最大50メートルしか生産されません。

この生地は私たちのパターンに合わせて裁断され、沖縄の國吉氏の工房で組み立てられます。

國吉氏は、私たちのレザージャケットと同じように、一着ずつ機械で縫い上げています。

ロゴマークは、ベトナム戦争時に米軍基地の兵士のスーベニアジャケットの装飾を始めた沖縄の小さな刺繍屋さんで施されます。

2013年、LLのDerekはここで偶然にもジーンズメーカーの國吉さんと出会いました。

國吉さんはDerekが履いていたジーンズに気づき、話が弾んだ後、近くの國吉さんの工房を訪れ、Derekがその縫製の良さと品質に感動し、一緒にジーンズを作ることになったのです。

ポケットバッグにはLewis Leathersのロゴが手刺繍されています。

- 洗濯:このジーンズは洗濯済みなので、すぐに履くことができます。

- その後の洗濯:このロープ編みスタイルのデニムのファンなら、最初の洗濯の前に3ヶ月から6ヶ月間着用することで、ユニークで好ましい色落ちの特徴を促すことができることをご存知でしょう。

ークインディゴデニムは、ストレスや磨耗により、独特の微妙なブルーシェードが現れ、あなたの生活のスナップショットのようになります。

- 洗濯の前に:ジーンズのフライボタンを閉め、裏返しにして低温で洗濯することをお勧めします。決して20度以上では洗わないで下さい。

そうすることで、生地が染料を最も長く保つことができ、ジーンズの経年変化による究極の自然な色落ちを作り出すことができます。

ーンズは長く愛用できるだけでなく、見た目も美しくなります。